Assembling a Walking Motor

In order to enable locomotion beyond the limited stroke of an individual actuator, we can assemble a walking motor which produces long-range motion through small repeated steps.

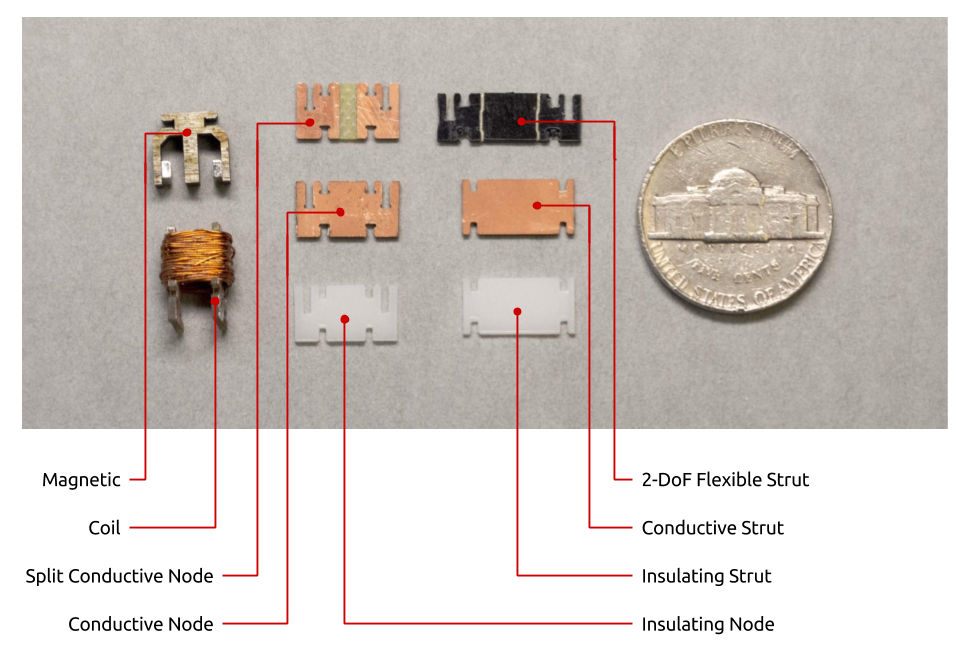

This device is assembled from a small-set of standardized parts. This includes three node part-types (conducting, insulating, and split-conductive), three strut part-types (conducting, insulating, and 2-DoF flexural), and two actuator part-types (coil and magnetic).

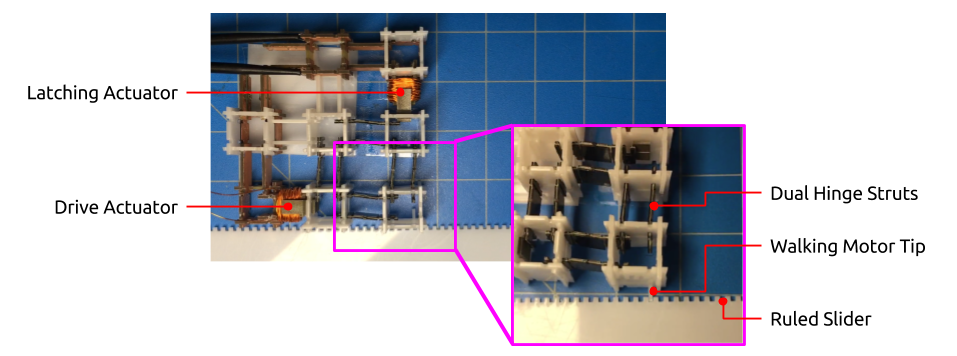

The walking motor is powered by two orthogonally oriented voice coil actuators. The stroke of one actuator, the "drive" actuator, is arranged to be parallel to the direction of long-range travel. The other actuator, or "latching" actuator, is used to engage and disengage the motor tip with a ruled slider. These actuations are transferred to the motor "tip" through a number of double-hinge struts which are arranged to enable independent vertical and horizontal shearing motions.

For initial testing we use a ruled slider to demonstrate how a series of small steps can create long-range motion. The slider has 1mm wide notches with a pitch between notches of 2mm.

The video below shows the development and prototyping of this motor: evolving from a manually driven test of the mechanism, to an actuated test, and finally showing its integration ruled slider to enable long-range motion.

In this experiment, the voice coil actuators are driven with conventional off-board electronics; in future work we will be integrating logic and electronics within the same assembly architecture, enabling the assembly of the sequencing of the drive signals.

Each voice coil actuator is driven by an H-Bridge motor driver and controlled by an ATmega32u4 microcontroller. In this experiment, the voice coils are driven with sinusoidal waveforms, one phase-shifted by 90 degrees. With a 800mA main current supply, repeatable motion can be obtained. Beyond 1A main current supply, the actuators can only be used for a limited time before their temperature rises to potentially damaging levels.

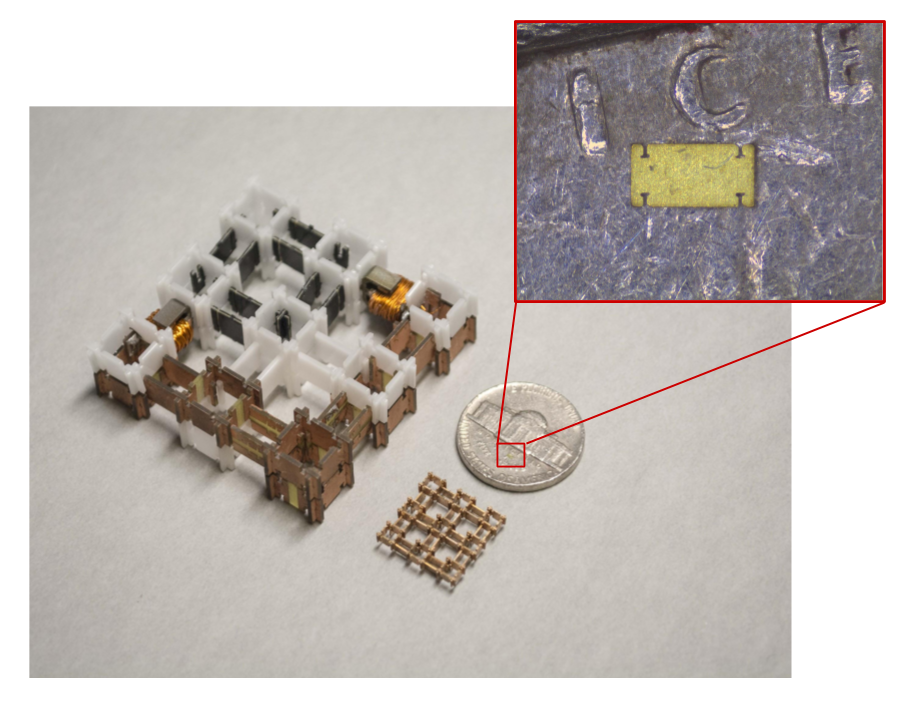

I constructed the first working prototype from centimeter-scale parts. Eventually we are aiming to scale this approach down to millimeter (and perhaps eventually micro-scale) parts. Pictured here is the current working prototype next to the same geometry assembled from millimeter scale parts.