Scaling

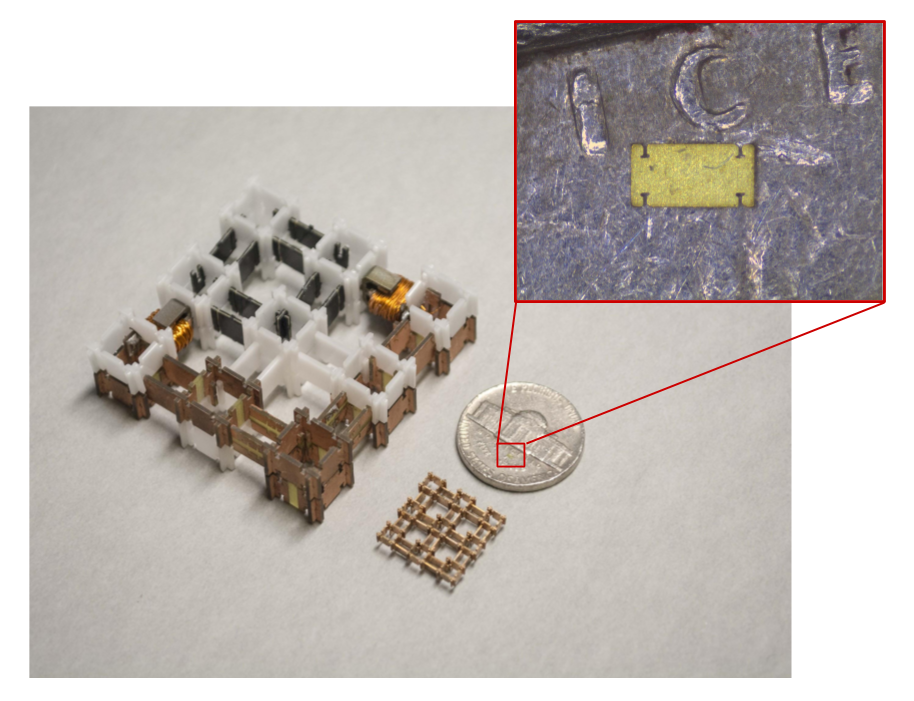

The flexibility of this building system enables fabrication at a variety of length-scales using a variety of processes. We have been prototyping these structures at a variety of scales. With centimeter scale prototypes, we have begun exploring the functional properties of the materials and developing complex systems that can be assembled from simple functional parts. At a smaller scale, we’ve been developing methods of assembly for millimeter scale parts. And at an even smaller scale, we have been working on methods of fabrication for the targeted sub-millimeter scale parts. In stages we will be scaling down the centimeter scale work to milli- and micro-scales. Figure 2 (right) shows a walking motor assembled at the centimeter scale next to a model of the same system at the millimeter scale.

While I have been initially prototyping with centimeter scale parts, eventually, I will be targeting the assembly of millimeter, and potentially sub-millimeter, parts:

The millimeter parts are made using the Wire-EDM with the 0.004" wire, which cuts with about a 0.007" kerf.

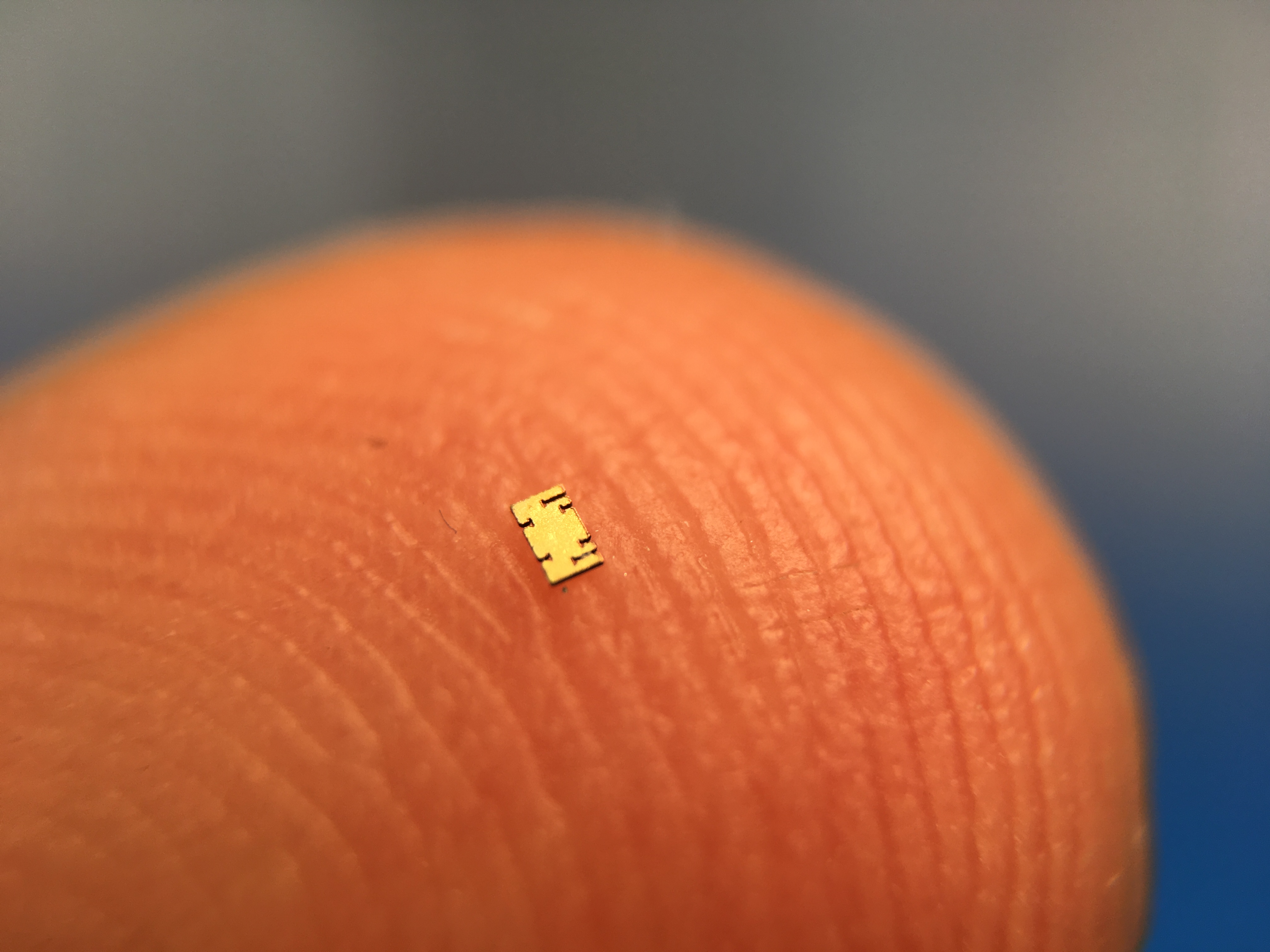

Below this scale, we can make parts using the Oxford micromachining Laser which has a kerf of about 20um. These parts are 75um thick and are 1mm long in their longest dimension.

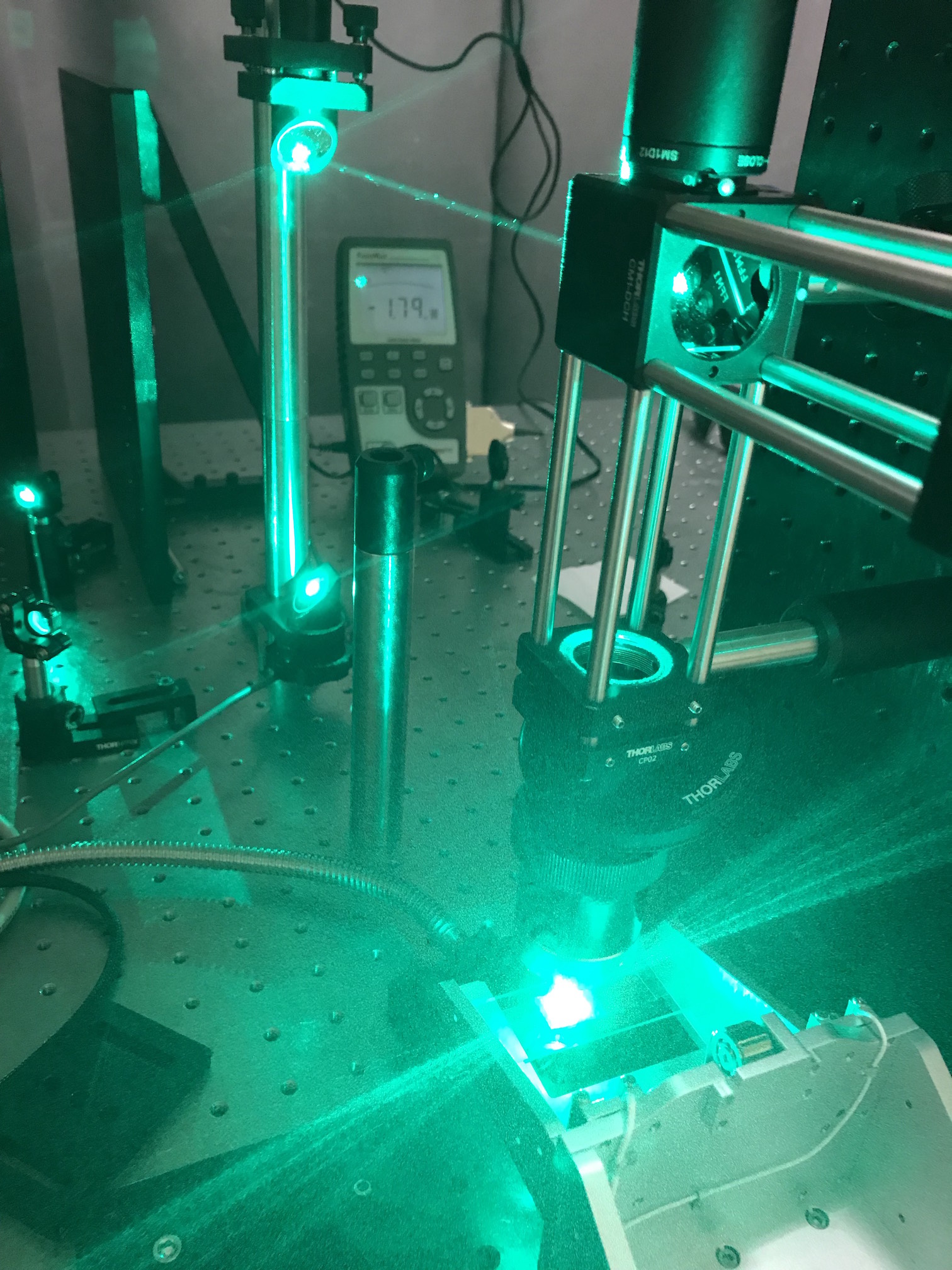

Even below this scale, we're getting our Pharos femtosecond machining laser online with which we should be able to approach micron feature sizes.

With our first few cuts on the laser, we produced these parts (below). They are just half a millimeter in their longest dimension with feature sizes of approximately 30um (limited by the thickness of material we had available).

To put this in perspective, here it is on a quarter: