Mechanism

Fabrication

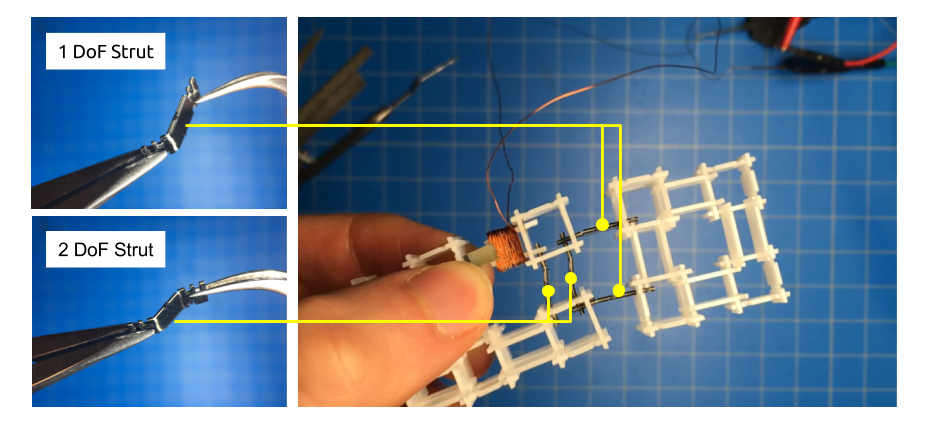

Mechanisms can be assembled by using parts with embedded flexural joints.

Three part-types are useful for assembling a wide variety of mechanisms; these include one, two, and three degree-of-freedom parts.

These parts can be efficiently manufactured using a laminate construction technique. Individual layers are laser machined and subsequently bonded together using a flexible double-sided tape.

In order for these parts to rigidly connect with other parts in this construction system, the thickness of the laminate needs to match the standard part-thickness. I performed a series of experiments to determine a tape/material combination with adequate thickness and ultimately settled on using 0.0125" delrin with ~6mil 3M 410M double-sided tape.

When laser cutting the individual layers, tabs are used to keep parts attached to a scaffold structure. Unfortunately this results in many little parts that need to be picked off with tweezers.

The double-sided tape is also machined on the laser. With careful control of the laser speed and power, it's possible to cut through just the tape but not through the backing.

I use a simple jig to align the individually machined layers and press it together using an acrylic roller.

While the alignment between layers is not perfect, it is sufficient to make a solid connection with neighboring parts.

Assembly

Once fabricated, these parts can be assembled to form a variety of linkages and mechanisms.